-

Dec. 27

2024

What Is a Wafer Back Grinding WheelThe wafer back grinding wheel is a special grinding wheel used in semiconductor manufacturing or electronic component processing. Its main function is to grind and polish the backside of the wafer to ...View More -

Dec. 12

2024

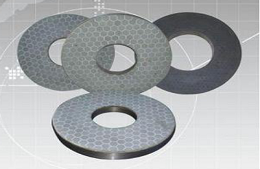

The Application and Advantages of Double Disc Grinding WheelsApplication fields of double disc grinding wheelsAutomobile partsIn the automotive manufacturing industry, double disc grinding wheels are mainly used for the precision machining of critical component...View More -

Nov. 15

2024

Everything You Need to Know About Cut-off WheelsResin-bonded super abrasives cut off wheels, consisting of diamond or cubic boron nitride (CBN) abrasives and a resin binder, are indispensable cutting tools for industrial cutting, widely applied in ...View More -

Oct. 25

2024

Resin Bond Grinding Wheels: Efficient GrindingResin bond grinding wheels are a type of consolidated abrasive tool that uses resin as a bonding agent to consolidate abrasive grains into a definite shape. These wheels are made by mixing resin with ...View More -

Oct. 10

2024

Precision Cutting Wheels: Durable and SharpPrecision cutting wheels are specialized abrasive tools used for high-precision cutting, widely applied in fields such as mechanical manufacturing, electronics, automotive, and aerospace. Precision cu...View More -

Sep. 25

2024

The Potential of CBN Grinding in Improving Production Efficiency and Reducing CostsWith continuous advancements in industrial manufacturing technology, the demand for production efficiency and cost control is also increasing. One of the many technological advancements driving this p...View More -

Jun. 21

2024

Advances in Semiconductor Cutting Technology: Innovations in New Blades and WheelsThe rapid development of semiconductor technology has set higher requirements for the precision and efficiency of material processing. With the growing demand for more powerful and efficient electroni...View More -

May. 24

2024

Techniques and Strategies for Improving the Cutting Efficiency of Disco Saw BladesDisco saw blades as sharp tools in the field of industrial cutting, their cutting efficiency is directly related to production efficiency and cost control. In order to maximize the performance of disc...View More -

May. 17

2024

The Important Role of Abrasive Stick Dresser in Wheel MaintenanceAs an important part of the vehicle, the performance and state of the wheel are directly related to the safety and stability of the vehicle. In the maintenance process of the wheel, the abrasive stick...View More -

May. 10

2024

Applications of Metal Bond Grinding WheelsAs an important tool in the grinding process, metal bond grinding wheels have attracted much attention because of their excellent performance and wide application fields. This paper will discuss the a...View More -

May. 03

2024

Exploring the Advantages of Double Disc Grinding WheelsAs an important tool for industrial grinding, the performance and shape design of grinding wheel directly affect the processing efficiency and workpiece quality. In recent years, the double disc grind...View More -

Apr. 26

2024

The Role of Diamond Dressing Roller in Maintaining Grinding Wheel PerformanceGrinding wheel is an important industrial grinding tool, and its stability and durability are directly related to processing efficiency and product quality. As the key tool of grinding wheel maintenan...View More -

Apr. 19

2024

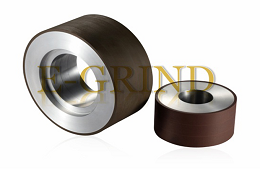

Building Partnerships with Centerless Grinding Wheel SuppliersIn the manufacturing industry, it is important to establish long-term and stable relationships with excellent centerless grinding wheel suppliers to improve product quality, reduce costs, and enhance ...View More -

Apr. 12

2024

Wafer Grinding Wheel Technology for Wafer ProcessingIn the semiconductor industry, wafer processing is a crucial link, and wafer grinding wheel technology as one of the key processes in wafer processing, its performance and precision directly affect th...View More -

Apr. 05

2024

Maintenance and Care of Bruting WheelThe wheel, as an important part of the vehicle, its intact state is directly related to the safety and stability of driving. However, in daily use, the wheel will inevitably suffer from wear, damage, ...View More -

Mar. 22

2024

Innovations and Advancements in Vitrified Cbn TechnologyVitrified CBN (Cubic Boron Nitride) technology has revolutionized the world of grinding and cutting applications. Known for its exceptional hardness and heat resistance, vitrified CBN has become the m...View More -

Mar. 15

2024

Factors Influencing the Performance of Vitrified CBN ToolsVitrified CBN (cubic boron nitride) tools have revolutionized the cutting and grinding industry, providing exceptional performance in demanding applications. Vitrified CBN, a composite material consis...View More -

Mar. 08

2024

A Comprehensive Comparison: Vitrified CBN and Other Abrasive MaterialsIn the world of abrasives, there are various options available for precision grinding applications. Each abrasive material offers unique qualities and benefits for specific use cases. In this blog pos...View More -

Mar. 01

2024

Exploring the Superiority of Vitrified CBN ToolsUnveiling the Cutting-edge RevolutionIn the realm of advanced abrasives, vitrified Cubic Boron Nitride (CBN) tools have emerged as a cutting-edge revolution, surpassing traditional grinding methods an...View More -

Feb. 23

2024

Factors to Consider When Selecting Vitrified Diamond Grinding WheelsWhen it comes to selecting the right grinding wheels for precision grinding tasks, vitrified diamond grinding wheels have become increasingly popular. With their exceptional hardness and prolonged dur...View More -

Feb. 16

2024

Unveiling the Secrets to Proper Usage and Maintenance of Vitrified Diamond Grinding WheelsVitrified diamond grinding wheels are an essential tool for various applications in industries such as metalworking, woodworking, and automotive. With their remarkable cutting efficiency and durabilit...View More -

Feb. 09

2024

A Comprehensive Guide to Types and Classifications of Vitrified Diamond Grinding WheelsVitrified diamond grinding wheels are powerful tools used in various industries for precision grinding applications. Their exceptional cutting ability and durability make them a popular choice for mat...View More -

Feb. 02

2024

Exploring the Advantages of Vitrified Diamond Grinding WheelsIn the realm of abrasive tools, vitrified diamond grinding wheels stand out as champions of precision. These advanced grinding wheels are crafted by combining synthetic diamond crystals with a vitrifi...View More -

Jan. 18

2024

Building Tomorrow: The Construction Industry's Dependence on Metal Bond Grinding WheelsThe construction industry stands as a testament to human ingenuity and the continuous quest for innovation. At the heart of this transformative sector lies the pivotal role played by metal bond grindi...View More -

Jan. 04

2024

In Pursuit of Perfection: How Metal Bond Grinding Wheels Elevate PrecisionIn the intricate world of precision machining, the pursuit of perfection is a relentless journey. At the heart of this pursuit lies the choice of grinding tools, with metal bond grinding wheels emergi...View More -

Dec. 21

2023

Metal Mastery: Exploring the Advantages of Metal Bond Grinding WheelsIn the realm of precision machining, the choice of grinding tools plays a pivotal role in determining the quality and accuracy of the finished product. Metal bond grinding wheels, known for their dura...View More -

Dec. 14

2023

Grinding Excellence: the Key Role of Surface Grinder Dressing ToolsIn the world of precision machining, achieving grinding excellence is a quest for perfection. The surface grinder, a vital tool in this pursuit, relies on precision dressing to maintain its effectiven...View More -

Oct. 19

2023

Wheel selection and operationNormally during work the outer diameter of the grinding wheel should be selected as large as possible to improve the circumferential velocity of the grinding wheel, which is beneficial to improve the ...View More -

Sep. 25

2023

Precision at Its Finest: How Electroplated Tools Redefine Cutting and GrindingIn the world of manufacturing and engineering, precision is the key to achieving exceptional results. The quest for precision has led to remarkable innovations in tooling, and one such game-changer is...View More -

Sep. 10

2023

Innovation in Tooling: Exploring the Advantages of Electroplated ToolsIn the ever-evolving world of manufacturing and engineering, innovation in tooling plays a vital role in pushing the boundaries of what is possible. Among the groundbreaking advancements in tooling te...View More -

Aug. 24

2023

Why need to dress the grinding wheel?During the grinding process, the state of the grinding wheel directly affects the grinding results. The state of the grinding wheel, such as changes in cutting ability and wheel shape, can have an imp...View More -

Aug. 20

2023

Cutting with Finesse: Mastering Craftsmanship with Precision Cutting WheelsIn the world of craftsmanship and manufacturing, achieving precision in cutting is an art form. Whether it's metal, stone, ceramics, or composites, the ability to cut with finesse is a hallmark of...View More -

Aug. 10

2023

Enhancing Cutting Accuracy: Exploring the Advantages of Precision Cutting WheelsIn industries that rely on cutting processes, precision is paramount. Achieving accurate and consistent cuts is essential for producing high-quality products and optimizing manufacturing efficiency. T...View More -

Jul. 20

2023

Beyond Facets: the Crucial Role of Bruting Wheels in Diamond ManufacturingWhen we think of diamonds, the first thing that comes to mind is their dazzling facets that reflect light in mesmerizing ways. However, there's more to the story of diamond manufacturing than just...View More -

Jul. 13

2023

Shaping Perfection: Unleashing the Power of Bruting WheelsIn the world of diamond cutting and shaping, achieving perfection and brilliance is the ultimate goal. This pursuit of excellence is made possible by a critical tool known as the bruting wheel. Brutin...View More -

Jun. 25

2023

Grinder Dressing Stick: The Secret Tool to Maintain Optimal Grinder Performance IntroductionIn the world of machining and grinding, precision and efficiency are paramount. Grinding wheels play a crucial role in achieving these goals, but over time, they can lose their sharpness and shape due...View More -

Jun. 15

2023

Achieving Precision and Longevity: Why the Grinder Dressing Stick is EssentialIn the world of machining and grinding, achieving precision and longevity in the grinding process is essential for producing high-quality and consistent results. A critical tool that plays a vital rol...View More -

May. 01

2023

Advantages of Metal Bonded Diamond Grinding WheelsMetal bonded diamond grinding wheels are widely used in various industries due to their unique properties and numerous advantages. In this article, we will explore the advantages of metal bonded diamo...View More -

Apr. 22

2023

Why Metal Bond Diamond Wheels Are Not Used for Grinding Steel Components?Metal bond diamond wheels are a popular choice for grinding hard and brittle materials such as glass, ceramics, and composites. However, they are not the ideal choice for grinding steel components. In...View More -

Apr. 15

2023

What is the Recommended Lifespan for Resin Bonded Grinding Wheels?Resin bonded grinding wheels are an essential tool in many industries, used to remove material from a workpiece and achieve a desired finish. Like any tool, grinding wheels have a limited lifespan, an...View More -

Apr. 08

2023

A Deep Dive into Resin Bond Grinding WheelsGrinding wheels are an essential tool in the manufacturing industry, used to remove material from a workpiece to achieve a desired shape or finish. The bond material used in grinding wheels plays a cr...View More -

Apr. 01

2023

Resin Bond Grinding Wheels: What They Are and How They WorkResin bond grinding wheels are an essential tool in the manufacturing industry. They are used to remove material from a workpiece, typically metal, to achieve a desired shape or finish. These grinding...View More -

Mar. 17

2023

How to choose wheel diameterThe outer diameter of the grinding wheel should be selected as large as possible to improve the circumferential velocity of the grinding wheel, which is beneficial to improve the grinding productivity...View More -

Mar. 17

2023

Characteristics of CBN grinding wheelThe hardness of CBN is higher than that of conventional abrasive. High hardness means stronger and sharper cutting ability; CBN has high wear resistance, which means it is more difficult to wear than ...View More -

Mar. 17

2023

Bond type of superabrasive(Diamond&CBN) grinding wheelsBond is a binding material to hold abrasive particles. Most of the grinding wheel is made up of bond and abrasive grains. The grinding wheel consists mainly of four elements: "abrasive", &qu...View More -

Feb. 20

2023

Characteristics Of Ceramic Bond CBN Grinding WheelCeramic bonded CBN grinding wheel represents a main development direction of abrasive products today and has a very broad application prospect.View More -

Feb. 20

2023

Bonding Agent For Grinding WheelThe substance used to bond abrasive in grinding wheel is called binder. Binder determines the strength, hardness, heat resistance and corrosion resistance of grinding wheel.View More -

Feb. 20

2023

Design Of Resin Bonded Diamond ToolThe design of resin-bonded diamond tools is mainly based on the following five aspects.View More -

Feb. 20

2023

Dressing Method Of Metal Bond Grinding WheelThe dressing technology of metal bonded grinding wheels has always been its research focus.View More -

Jan. 01

2023

How To Choose CBN Grinding Wheel And Diamond Grinding Wheel?CBN grinding wheel (cubic boron nitride) is mainly used for grinding hard and tough materials, and cannot replace diamond SDC grinding wheel for grinding cemented carbide and nonmetallic hard materials.View More -

Nov. 02

2022

What Factors Are Affecting the Life of Grinding Wheels?In general, "abrasive grains" and "bonds" (binders, cementing matrix, bond materials) are used to describe diamond grinding wheels. At the manufacturing stage, both are in the form of "powder," which is then shaped and sintered to create a diamond grinding wheel.View More

English

Efficient Grinding Solution

Efficient Grinding Solution

-

Products

Resin Bond Grinding Wheels Vitrified Bond Grinding Wheels Metal Bond Grinding Wheels Electroplated Tools Dicing Blade & Grinding Wheels For Semi-Conductor Grinding Wheel Dressing ToolCut Off Wheels Grinding Wheels For Woodworking Tools Tool & Cutter Grinding Wheels Grinding Wheels For Die & Tooling Centerless Grinding Wheels Resin Bond Double Disc Grinding Wheels Tissue Paper Knife Grinding Wheel Economical Grinding Wheels

-

Company

- Resources

- News & Blog

- Contact Us