In the realm of precision machining, the choice of grinding tools plays a pivotal role in determining the quality and accuracy of the finished product. Metal bond grinding wheels, known for their durability and versatility, stand out as a cornerstone in achieving metal mastery. This blog delves into the advantages that metal bond grinding wheels bring to the world of machining.

Understanding Metal Bond Grinding Wheels

The Core of Durability

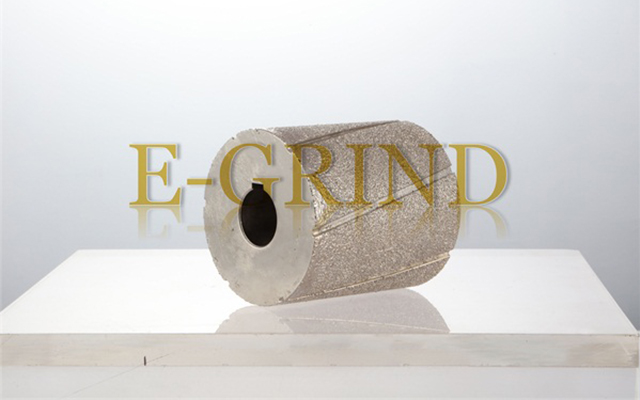

Metal bond grinding wheels are crafted with a matrix of metal, typically bronze or other alloys, holding the abrasive particles in place. This robust construction imparts a high level of durability to the wheel, making it well-suited for tasks that demand longevity and consistent performance.

Versatility in Application

Metal bond grinding wheels exhibit remarkable versatility in application. Whether it's precision surface grinding, edge profiling, or intricate form grinding, these wheels can handle a broad spectrum of tasks. The ability to adapt to various materials and grinding conditions makes them indispensable in diverse machining scenarios.

Advantages of Metal Bond Grinding Wheels

Extended Lifespan

One of the primary advantages of metal bond grinding wheels is their extended lifespan. The robust metal matrix effectively supports the abrasive particles, reducing wear and tear. This longevity not only enhances productivity but also minimizes the frequency of wheel replacements, contributing to cost-effectiveness.

Consistent Performance

Metal bond grinding wheels offer consistent and predictable performance throughout their lifespan. The stable bond ensures that the abrasive particles maintain their cutting efficiency, delivering a uniform and precise finish. This consistency is especially critical in industries where tight tolerances are paramount.

Enhanced Precision

Achieving superior precision is a hallmark of metal bond grinding wheels. The rigid metal matrix provides exceptional control over the wheel's shape and profile, allowing for intricate and detailed grinding. This precision is invaluable in applications where intricate geometries or complex forms need to be maintained.

Cooler Grinding Temperatures

Metal bond grinding wheels exhibit excellent heat dissipation properties. The metal matrix efficiently conducts heat away from the grinding area, preventing overheating and thermal damage to the workpiece. This characteristic is particularly advantageous when working with heat-sensitive materials or during extended machining sessions.

Best Practices in Using Metal Bond Grinding Wheels

Optimal Operating Parameters

To maximize the advantages of metal bond grinding wheels, operators should adhere to optimal operating parameters. This includes selecting the appropriate wheel specifications, maintaining recommended wheel speeds, and ensuring proper coolant flow to manage heat effectively.

Regular Maintenance

Regular inspection and maintenance are essential for preserving the performance of metal bond grinding wheels. Operators should routinely check for wear, trueness, and any signs of damage. Timely dressing of the wheel surface ensures consistent cutting efficiency.

Metal bond grinding wheels stand as a testament to the marriage of durability and precision in the world of machining. Their versatility, extended lifespan, and ability to deliver superior precision make them indispensable tools for industries that demand excellence in metal fabrication. As technology continues to advance, the mastery of metal bond grinding wheels contributes to the ongoing evolution of precision machining, setting new standards for quality and efficiency.