Cemented carbide is an alloy that is a mixture of tungsten carbide and cobalt, and is a material with features such as high-precision processing, good impact resistance, excellent abrasion resistance, and high hardness even at high temperatures. It is a popular material for cutting tools, end mills, molds and dies, etc.

There are many grades and types of cemented carbide, and most of them have a considerable "hardness" among metals. Its hardness is after CBN and diamond, and it is also heavy. For the grinding, polishing, and cutting of cemented carbide, a grinding wheel with diamond abrasive which is the hardest of all abrasive grains, is the best choice.

Diamond wheels have a wide range of particle sizes, from mesh sizes of 16, 20, 30, 40, 50, 60, 80, 100, 120, 140, 170, 200, 230, 270, 325 to micron sizes of 400 or finer, on the market. Generally, 120, 140 and 170 are often used in the rough process of cemented carbide.

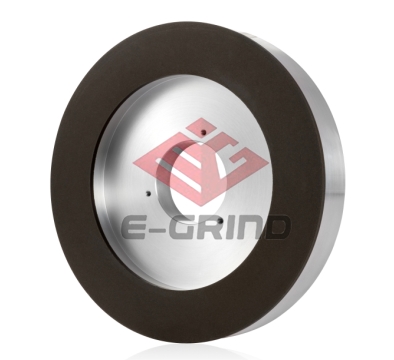

Features and specifications of grinding wheels for carbide grinding and polishing

The process often used in grinding

For carbide grinding and polishing, diamond grinding wheels can cover all processes from roughing to semi-finishing and finishing can be used in cylindrical grinding, surface grinding (flat grinding), internal grinding (inner grinding), etc.

Regarding the concentration (amount of abrasive grains), 75% to 100% are often used for cemented carbide.

Regarding hardness, N and P are often used for cemented carbide.