In the intricate world of precision machining, the pursuit of perfection is a relentless journey. At the heart of this pursuit lies the choice of grinding tools, with metal bond grinding wheels emerging as the vanguards of precision. This blog explores how these wheels elevate the quest for perfection in the realm of machining, unraveling the key mechanisms that contribute to their prowess.

The Precision Paradigm

Defining Precision in Machining

Precision in machining is synonymous with achieving exactness, accuracy, and repeatability in the production of machined components. The demand for precision is paramount across various industries, from aerospace and automotive to medical and electronics. Metal bond grinding wheels play a pivotal role in this precision paradigm, offering unique attributes that set them apart.

Unveiling the Features of Metal Bond Grinding Wheels

Rigid Metal Matrix

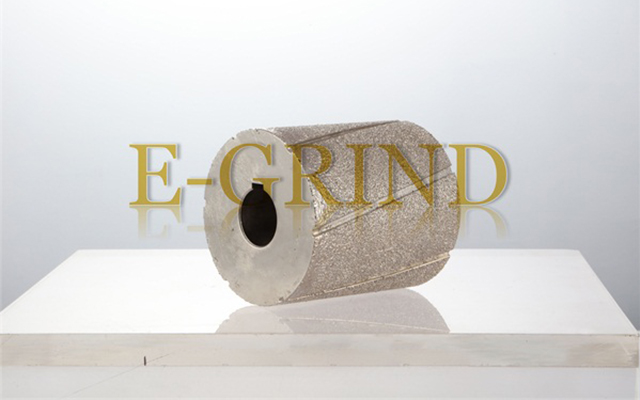

At the core of the precision elevation achieved by metal bond grinding wheels is their rigid metal matrix. Composed of materials like bronze or other alloys, this matrix firmly holds the abrasive particles in place, providing stability and control during the grinding process. The rigidity of the metal bond ensures that the wheel maintains its form, a critical factor in achieving precise outcomes.

Consistent Abrasive Performance

Metal bond grinding wheels deliver a consistent performance throughout their lifespan. The stability of the metal matrix ensures that the abrasive particles maintain their sharpness and cutting efficiency over extended periods. This consistency is a game-changer, especially in industries where maintaining tight tolerances and uniform surface finishes is non-negotiable.

Elevating Precision with Metal Bond Grinding Wheels

Microscopic Control in Forming

Precision machining often involves intricate forms and complex geometries. Metal bond grinding wheels excel in providing microscopic control over the shaping and profiling of workpieces. The ability to achieve fine details and maintain intricate shapes contributes to the elevated precision sought in demanding applications.

Reduced Dimensional Variations

In the pursuit of perfection, dimensional variations must be minimized. Metal bond grinding wheels, with their stable and controlled grinding action, contribute to reducing dimensional variations in machined components. This attribute is especially crucial in industries where components must meet stringent specifications and fit seamlessly into larger assemblies.

Operational Best Practices

Optimal Wheel Selection

Selecting the optimal metal bond grinding wheel is the first step toward achieving precision. Considerations such as abrasive type, bond hardness, and grit size should align with the specific requirements of the machining task. The right wheel selection is the foundation upon which precision is built.

Precision Grinding Parameters

Fine-tuning grinding parameters is essential for maximizing the precision capabilities of metal bond grinding wheels. Operators should adhere to recommended speeds, feeds, and depths of cut to ensure that the wheel performs optimally and consistently.

In the relentless pursuit of perfection in machining, metal bond grinding wheels stand as instrumental allies. Their rigid metal matrix, consistent abrasive performance, and microscopic control elevate precision to unprecedented levels. As industries continue to push the boundaries of what is achievable in precision machining, the contribution of metal bond grinding wheels becomes increasingly invaluable. In the hands of skilled operators, these wheels become the tools of choice for those who refuse to compromise on precision in their pursuit of perfection.