Application Fields of Double Disc Grinding Wheels

Automobile parts

In the automotive manufacturing industry, double disc grinding wheels are mainly used for the precision machining of critical components. For example:

Brake pads

Precisely machining their end faces to ensure flatness and thickness consistency, thereby guaranteeing the performance and safety of the braking system.

Clutch plates

Enhancing the parallelism and surface roughness of components through efficient double-end surface grinding to meet the demands of high-speed transmission systems.

Transmission gears

Gears machined with double-end grinding wheels have smoother end faces, significantly improving the meshing accuracy and lifespan of the gears.

Mechanical seals in the air conditioning industry

In the air conditioning industry, mechanical seals are crucial for ensuring the system's sealing performance and operational efficiency. Double disc grinding wheels are used in the processing of the following seals:

Rotating and stationary rings

Their flatness and smoothness directly affect sealing effectiveness. Using double-end grinding wheels can significantly improve machining accuracy, reducing the risk of leaks.

Seal gaskets

Ensuring that seal gaskets have highly consistent thickness and surface quality through efficient grinding, thereby enhancing the stability of the air conditioning system.

Air compressor components

Several key parts of air compressors rely on double disc grinding wheels for high-precision machining, such as:

Valve plates and seats

Ensuring the flatness and matching of their end faces through grinding, reducing compressor leakage and improving efficiency.

Rotating components

Post-processing parts have higher symmetry and parallelism, thus reducing vibration and noise and extending the equipment's lifecycle.

Automobile oil pump parts

As a core component of the automobile power system, the automobile oil pump requires extremely high machining precision. The application of double disc grinding wheels mainly includes:

Rotors and stators

Enhancing the flatness and smoothness of end faces through precise grinding, ensuring stability and durability during high-speed operation of the oil pump.

Gear end faces

High-precision machining allows smoother gear transmission, effectively improving pump efficiency while reducing energy consumption.

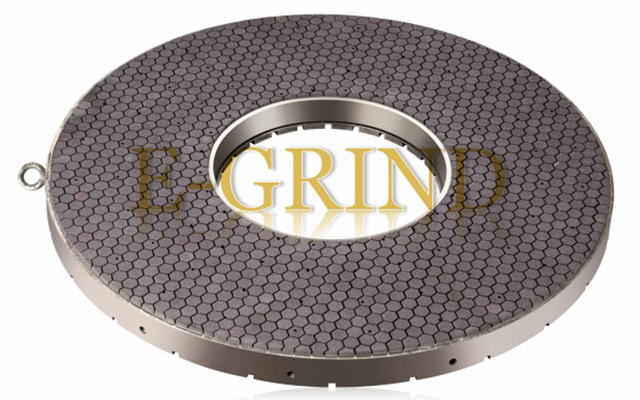

Advantages of E-Grind Double Disc Grinding Wheels

Precise flatness and reliability

E-Grind double disc grinding wheels are renowned for their precise flatness and can maintain stability under high-load operations. Their unique structural design effectively prevents wheel roll-off and fragmentation, significantly enhancing safety and product longevity. This performance not only ensures machining accuracy but also reduces production interruptions caused by wheel damage.

Significant improvement in cutting efficiency and reduced processing time

Double disc grinding wheels employ advanced cutting technology that can significantly increase cutting rates. Their optimized grinding performance can effectively reduce processing time, helping users complete more work in a shorter period, thus improving overall production line efficiency.

Significantly reduced operating costs

The high-performance design and material selection make double disc grinding wheels more durable with a lower wear rate. Compared with traditional grinding wheels, their more durable characteristics reduce the need for frequent replacements and maintenance, thereby lowering operating costs. Additionally, improved processing efficiency also means less energy consumption and manpower.

Maintaining a clean worksite

Double disc grinding wheels reduce dust and debris generation during use, helping to keep the machining area clean. This not only improves workshop environment comfort but also provides operators with a healthier work setting.

Significantly reduced cleaning workload

Optimized design ensures that waste discharge during cutting is more concentrated and controllable, reducing cleaning time. This feature saves users extra cleanup work, further enhancing work efficiency.

In summary, E-Grind double disc grinding wheels integrate high precision, high efficiency, low cost, and environmental protection, making them indispensable quality tools in the industrial processing field, providing users with comprehensive technical and economic advantages.