In the world of machining and grinding, precision and efficiency are paramount. Grinding wheels play a crucial role in achieving these goals, but over time, they can lose their sharpness and shape due to wear and tear. The secret tool that helps maintain optimal grinder performance and ensures consistent results is the grinder dressing stick. Often overlooked, this simple yet powerful tool is a game-changer in the machining industry. In this blog, we will delve into the significance of the grinder dressing stick, its role in maintaining grinder performance, and the benefits it brings to the overall grinding process.

Unveiling the Grinder Dressing Stick

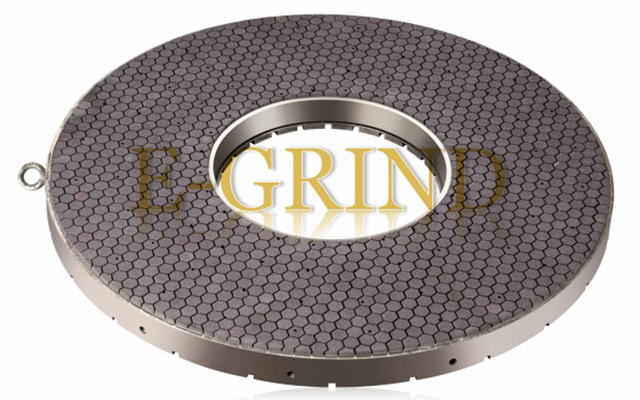

The grinder dressing stick, also known as a dressing stone or dressing tool, is an abrasive tool used to dress or true the surface of grinding wheels. It is designed to remove built-up metal chips, worn abrasive particles, and other impurities from the grinding wheel's surface, restoring its original shape and sharpness. Dressing sticks are crafted from high-quality abrasive materials, and they come in various shapes and sizes to accommodate different types of grinding wheels and specific requirements.

Ensuring Optimal Grinder Performance

A well-maintained diamond abrasive wheel with the help of a dressing stick retains its original shape and profile. This ensures that the grinding wheel delivers precise and uniform results, essential for achieving accurate and consistent machining. A dressing stick significantly improves the surface finish of the workpiece. By exposing fresh and sharp abrasive particles, the dressing process enhances the grinding wheel's cutting action, resulting in a smoother and finer surface texture.

Extending Grinder Wheel Longevity

Grinding wheels experience gradual wear during operation, but excessive wear can lead to premature replacement. Regular dressing with a dressing stick reduces wheel wear by preventing the accumulation of debris and promoting even distribution of abrasive grains. Wheel glazing occurs when the grinding wheel's surface becomes polished and loses its cutting ability. Utilizing a dressing stick prevents glazing by breaking down the bond between abrasive grains, exposing fresh cutting edges, and restoring the wheel's cutting performance.

Versatility and Cost-Effectiveness

As a typical tupe of abrasive wheel dressing tool, the grinder dressing stick is versatile and compatible with various types of grinding wheels, including vitrified, resin-bonded, and diamond wheels. This adaptability makes it a valuable tool for a wide range of grinding applications. Regular dressing with a dressing stick extends the lifespan of grinding wheels, leading to cost savings for businesses. Reduced wheel replacement frequency translates to lower operational costs and increased productivity in machining processes. Efficient grinding is essential for meeting production deadlines and maintaining consistent product quality. The dressing stick optimizes grinding wheel performance, enhancing grinding efficiency and throughput.

The diamond wheel dressing stick is an indispensable tool in the machining industry, providing a simple yet effective solution to maintain optimal grinder performance. By ensuring the proper shape and sharpness of grinding wheels, this seemingly humble tool significantly impacts the quality and efficiency of the grinding process. Its role in preserving wheel shape, enhancing surface finish, and extending wheel longevity brings substantial benefits to businesses, including cost savings, enhanced safety, and improved productivity. Investing in regular dressing with a dressing stick is a wise choice for companies aiming to unlock the full potential of their grinding operations, achieving precision and efficiency that propel them to greater heights of success in the competitive world of machining.