Disco saw blades as sharp tools in the field of industrial cutting, their cutting efficiency is directly related to production efficiency and cost control. In order to maximize the performance of disco saw blades and enhance their cutting efficiency, it is essential to employ a range of technologies and strategies. This article will delve into four key areas to discuss how to enhance the cutting efficiency of disco saw blades.

Choose the Appropriate Disco Saw Blades Model and Specification

Initially, it is imperative to select the suitable disco saw blades model and specification based on the type, thickness, and hardness of the material being cut. Different saw blade designs cater to varied cutting needs, and choosing the correct disco saw blades can ensure a smoother cutting process, reducing instances of blade jamming and breaking, thereby enhancing cutting efficiency.

Optimize Cutting Parameters

The configuration of cutting parameters plays a pivotal role in the cutting efficiency of disco saw blades. Adjusting parameters such as cutting speed, feed speed, and cutting depth appropriately based on the material characteristics, the capabilities of the disco saw blades, and the capacity of the cutting equipment is crucial. Continuously refining these parameters can unveil the optimal cutting conditions, enabling the disco saw blades to maintain the best working state during the cutting process, which in turn boosts cutting efficiency.

Strengthen the Cooling and Lubrication of the Disco Saw Blades

Throughout the cutting operation, substantial friction heat is generated between the disco saw blades and the material. If not timely cooled and lubricated, this can lead to an increase in temperature of the disco saw blades, adversely affecting their cutting performance. Therefore, effective cooling and lubrication measures need to be implemented, such as applying coolant to lower the blades' temperature; concurrently, selecting a suitable lubricant to diminish the friction between the diamond dicing saw and the material, decrease the cutting resistance, and hence improve cutting efficiency.

Regular Maintenance of Disco Saw Blades

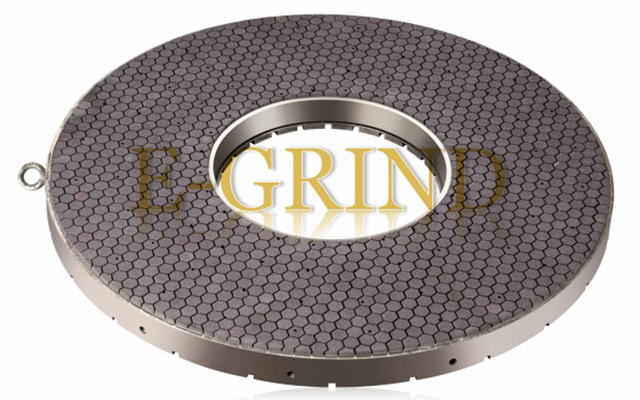

The performance and lifespan of disco saw blades are intimately associated with their upkeep. Most grinding disc manufacturers suggest that regular cleaning, inspection, and sharpening of the disco saw blades are necessary to ensure their surface is devoid of debris and remains sharp; additionally, the storage environment of the disco saw blades should be monitored to prevent moisture, rust, or other forms of damage. Through consistent maintenance and care of the disco saw blades, their optimal working condition can be preserved, extending their service life and, in turn, boosting cutting efficiency.

In conclusion, enhancing the cutting efficiency of disco saw blades necessitates a multifaceted approach. By selecting proper saw blade models and specifications, optimizing cutting parameters, reinforcing cooling and lubrication, and regularly maintaining the disco saw blades, the cutting efficiency of disco saw blades can be significantly improved, offering robust support for the production efficiency and cost control of businesses.