Unveiling the Cutting-edge Revolution

In the realm of advanced abrasives, vitrified Cubic Boron Nitride (CBN) tools have emerged as a cutting-edge revolution, surpassing traditional grinding methods and setting new standards in machining technology. This passage delves into the exceptional attributes that make vitrified CBN tools superior, revolutionizing industries and redefining the possibilities in precision machining.

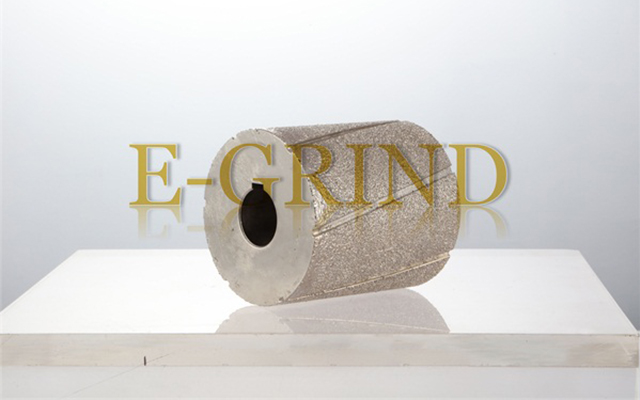

Vitrified CBN tools are renowned for redefining precision in machining. Cubic Boron Nitride, an extremely hard synthetic material, exhibits properties comparable to diamond, making it an ideal candidate for applications involving hard metals, superalloys, and other challenging materials. The vitrified bonding matrix, combined with CBN particles, creates a tool that excels in achieving tight tolerances, intricate shapes, and impeccable surface finishes. Industries requiring high-precision components, such as aerospace and automotive, are increasingly turning to vitrified CBN tools to elevate the quality of their machined products.

One of the standout features of vitrified CBN tools lies in their unparalleled durability. The vitrified bonding material not only securely holds the CBN particles but also contributes to the tool's robustness, allowing it to withstand the demands of heavy-duty machining. Whether it's grinding hardened steel or superalloys, vitrified CBN tools showcase exceptional resilience, resulting in extended tool life and reduced downtime for tool changes. This longevity translates into enhanced cost-effectiveness for industries where efficiency and productivity are paramount.

Vitrified CBN tools offer a level of versatility that expands their utility across a wide range of machining applications. The inherent hardness of CBN, combined with the flexibility of vitrified bonding, allows these tools to tackle materials that are traditionally challenging for other abrasives. From precision grinding of gears in the automotive sector to the machining of heat-resistant alloys in aerospace, vitrified CBN tools demonstrate adaptability and performance that make them indispensable in diverse manufacturing processes.

Advanced Technology: The Engineering Behind Vitrified CBN Tools

Understanding the superiority of vitrified CBN tools requires a glimpse into the advanced technology that goes into their manufacturing. The production process involves precise engineering and careful selection of materials to achieve the optimal combination of hardness, toughness, and thermal stability.

Manufacturers employ state-of-the-art techniques to ensure a uniform distribution of CBN particles within the vitrified matrix. This meticulous process is crucial for achieving consistent performance across the entire grinding wheel. The strategic arrangement of CBN particles contributes to the tool's ability to maintain sharp cutting edges, resulting in superior surface finishes and extended tool life.

The customization options available in the production of vitrified CBN tools allow manufacturers to tailor these abrasives to specific machining needs. Whether it's adjusting the concentration of CBN particles for different levels of aggressiveness or fine-tuning the vitrified bonding matrix for enhanced resilience, the ability to customize ensures that vitrified CBN tools can be optimized for various applications. This adaptability is a testament to the versatility and precision that define the superiority of vitrified CBN tools.

In conclusion, vitrified CBN tools stand at the forefront of machining technology, offering unparalleled precision, durability, and versatility. As industries evolve and demand higher performance from their machining processes, vitrified CBN tools emerge as indispensable assets, reshaping the landscape of precision grinding. From intricate components to challenging materials, the superiority of vitrified CBN tools paves the way for enhanced efficiency, reduced costs, and the attainment of machining perfection in modern manufacturing.