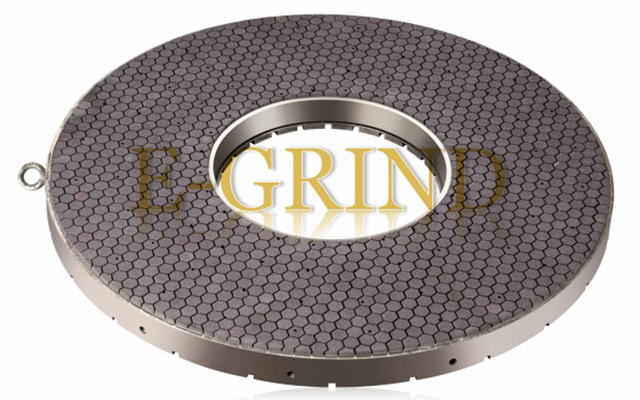

Wheel Specification: 1A1R 250x20x6x76 B107 V240 wet

Wheel Speed: 1500 RPM

Workpiece material: AISI430

Hardness: HB175

Problem: Wheel burns very much. Impossible to grind at all. They tried different feed, even finally set the machine to grind off 1 micron only, nothing helps. High noise. Also wheel is beating. Can not be repaired by dresser.

Reason: Wheel was not opening very well. There is run-out problem when put wheel on machine. Some of abrasive layer does not involve in the grinding process. And make high noise when grinding.

Suggestion: Use cast iron or silicon carbide rod to dress the wheel, do opening again before using.

New problem: Because of the old surface grinder, wheel can not be dressed by round dressing tool.

Solution: Let the wheel grind with copper block of 60mm width or larger. Or 45# steel block also works. Copper material is very soft and will not destroy the CBN grit edge when truing. We can complete the truing and opening by simulating the grinding process.